This article is part 2 of a 2 part series on engineering design reviews for mechanical engineers. In the first article, we covered how to plan and prepare for your design review. This article covers how to run your reviews effectively, capture actionable feedback that is useful, and close the loop to improve your designs.

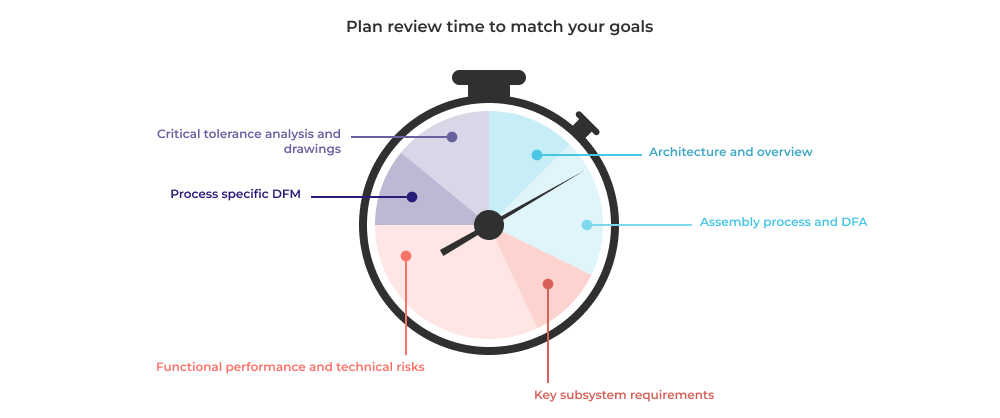

Your preparation for your design review should have you set up nicely to capture high quality design feedback from the right participants. In the remainder of this article, we’ll be focusing on practical guidance to help you achieve a few key goals.

The teams that hit these goals tend to iterate faster, discover issues before they become expensive, resolve more critical design issues per iteration, and deliver better products in less time.

You know better than anyone what you want out of your design review, so don’t be afraid to steer the discussion in that direction. If you are worried about a particular aspect of the design, or some set of risks, feel free to challenge your reviewers to address those areas. Good design reviews are not just feedback sessions, but rather in depth discussions about the tradeoffs and constraints that engineers are contending with. Ideally they should be fun. Consistent and thoughtful moderation can keep everyone focused on the most impactful areas of the design.

PRACTICAL GUIDANCE

Don’t let your design review go off the rails. Here’s a few tips to keep you on track and focused.

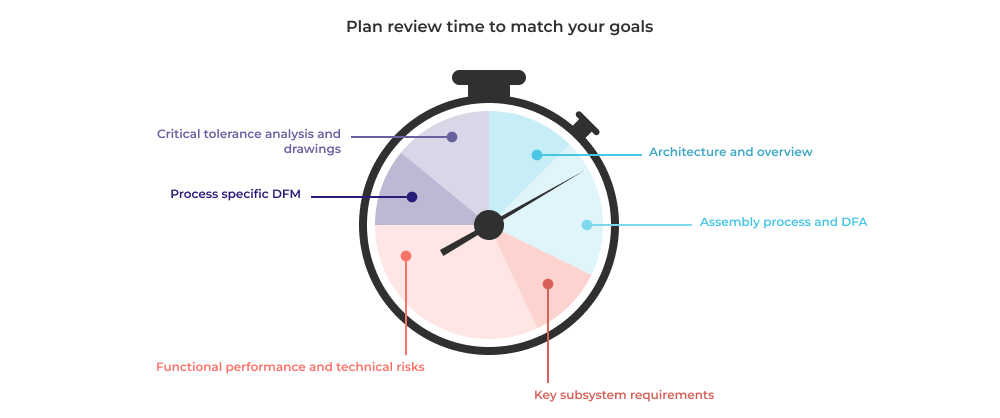

It may seem obvious, but it’s critical that every piece of feedback is captured during a design review. Otherwise what’s the point? Questions and suggestions may be coming at you left and right, so its important to designate at least one person to capture feedback. We’re pretty biased here, but we like to use issues in Five Flute to capture design review feedback. In fact, we built our SolidWorks add-in to make it easy to create visual issues and markup directly in CAD during remote reviews. Its the fastest way to share visual information and design context while keeping feedback connected to the parts and assemblies being reviewed, so nothing slips through the cracks.

PRACTICAL GUIDANCE

Here are a few considerations when capturing feedback from reviewers.

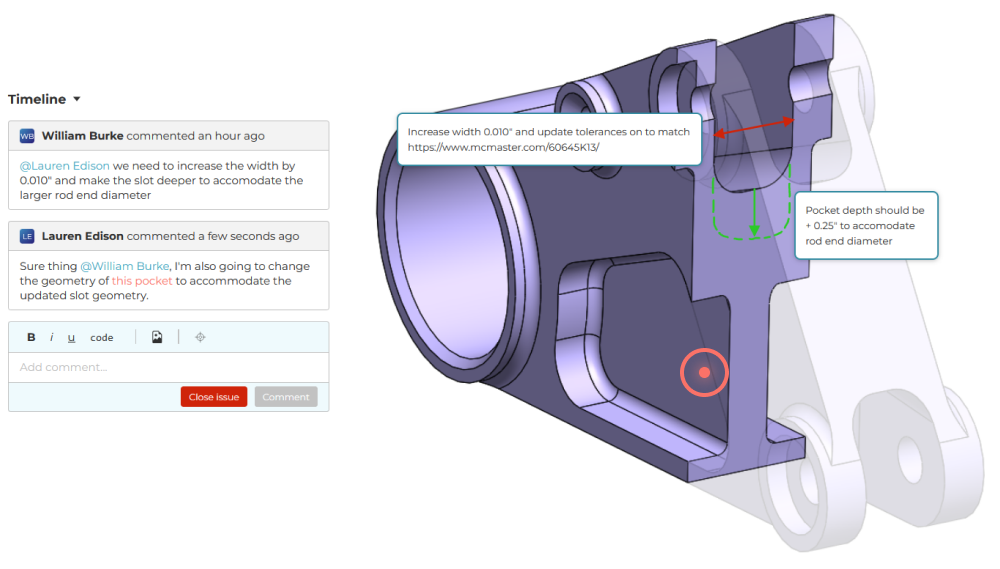

You lined up a great team of reviewers, locked down a meeting time that works for everyone, prepared background information and then spent 30 minutes trying to solve the first cool problem you discovered. Sound familiar? We’ve seen it happen countless times across a variety of hardware projects. Always remember that design reviews are about identifying issues, NOT solving them. It neglects the goals of the review and doesn’t respect the time your reviewers are taking out of their schedule to support your project.

discovery during reviews, not solutions" />

discovery during reviews, not solutions" />

PRACTICAL GUIDANCE

As a moderator of a great design review always remember the following:

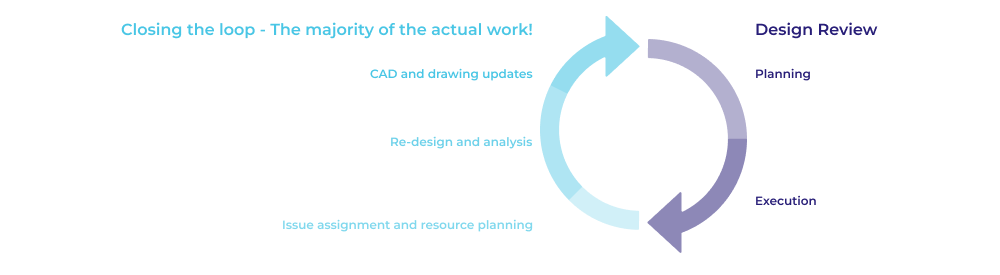

Now that you’ve addressed all your review goals and captured every bit of feedback its time to close the loop and fix the design. This may take a working session after your review, but the goal is to know what feedback needs to be addressed first and who is responsible for each issue.

PRACTICAL GUIDANCE

Closing the loop ensures high quality output, but it demands a rigorous approach. Be sure to do the following after every design review to get the best results out of your team.

If you are interested in building a system of record for your design review feedback, making better design decisions, and eliminating repeated engineering mistakes, check out Five Flute. It’s the fastest way to share, review, and improve your engineering designs. From engineering drawing reviews to 3D design reviews of complex parts and assemblies, Five Flute is built for modern engineering teams that want to move faster without making mistakes.